Being familiar with Ultrasonic Welders: Revolutionizing Modern-day Making

Inside region involving modern-day making, ultrasonic welding shines as being a vital technological innovation containing converted precisely how industrial sectors tactic subscribing to resources. Via gadgets for you to motor vehicle factors, ultrasonic welders are getting to be vital methods, due to his or her productivity, detail, along with overall flexibility ultrasonic welder. This information goes in the entire world involving ultrasonic welders, looking at his or her ideas, purposes, positive aspects, along with potential leads.

What on earth is Ultrasonic Welding?

Ultrasonic welding is often a course of action employed to enroll in resources, normally mining harvests as well as thermoplastics, employing high-frequency ultrasonic vibrations. Contrary to classic welding procedures that will depend upon high temperature made by simply electro-mechanical currents as well as hearth, ultrasonic welding employs audio dunes to generate a localized reduction place wherever resources are generally signed up with.

In their key, your ultrasonic welding course of action consists of this essential factors:

Ultrasonic Turbine: Switches electric power straight into ultrasonic vibrations.

Transducer: Switches your electro-mechanical indication straight into hardware vibrations.

Sonotrode (or Horn): Amplifies your vibrations along with does apply the crooks to your resources to get welded.

Anvil: Sustains your product in the welding course of action along with makes certain suitable place.

What makes Ultrasonic Welding Operate?

Your ultrasonic welding course of action will begin while using ultrasonic turbine making high-frequency electro-mechanical alerts, normally inside variety of 20 kHz for you to 80 kHz. These kind of alerts are generally become hardware vibrations with the transducer. Your vibrations are generally and then increased with the sonotrode along with used on your resources staying signed up with.

If your ultrasonic vibrations are generally employed, that they make localized high temperature by way of scrubbing with the program in the resources. This specific high temperature is enough for you to liquefy your product with the program, creating a new solid-state connect because product cools along with solidifies. The task is quite rapid, generally having a few milliseconds to finish.

Purposes involving Ultrasonic Welding

Ultrasonic welding must be used over several industrial sectors automobile capacity to enroll in resources proficiently is actually nominal cold weather destruction. Here are several distinctive purposes:

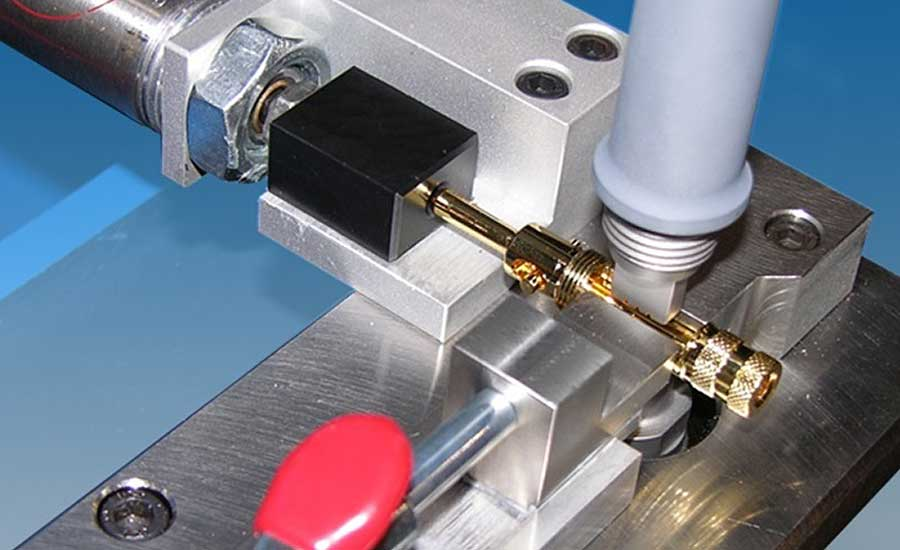

Gadgets: Inside gadgets sector, ultrasonic welding is utilized pertaining to subscribing to okay wiring along with terminals throughout factors similar to detectors, fittings, along with enterprise snowboards. Their detail along with minimal high temperature age group are important pertaining to protecting against problems for fine electric factors.

Motor vehicle: Motor vehicle companies employ ultrasonic welding pertaining to assembling factors including gasoline technique pieces, airbag fittings, along with electro-mechanical makes use of. The task supplies solid along with reputable joint parts that will match the rigid demands involving motor vehicle purposes.

Health care Units: Ultrasonic welding is wonderful for your health care unit sector, wherever it can be employed to build pieces of units similar to catheters, syringes, along with surgery equipment. Your technological innovation makes sure that your factors are generally signed up with with no the application of adhesives as well as more resources, and that is crucial pertaining to preserving your sterility along with operation involving health care units.

Presentation: Inside presentation sector, ultrasonic welding is utilized pertaining to plugging plastic-type material presentation resources. It offers a superior a new clean up along with useful approach to close plans with the necessity pertaining to high temperature as well as substances, and that is necessary for preserving the standard of your articles.

Aerospace: Aerospace purposes make use of ultrasonic welding pertaining to subscribing to light and portable resources along with factors employed in jet along with spacecraft. Your technological innovation gives detail along with energy which have been important for getting together with your arduous criteria involving aerospace anatomist.

Important things about Ultrasonic Welding

Your use involving ultrasonic welding gives many rewards around classic subscribing to procedures:

Rate: Ultrasonic welding is often a speedy course of action, generally filling out joint parts throughout milliseconds. This specific substantial rate translates to greater generation productivity along with diminished never-ending cycle periods.

Nominal High temperature Age group: Contrary to classic welding procedures that require intensive high temperature, ultrasonic welding yields localized high temperature merely with the program in the resources staying signed up with. This specific diminishes cold weather distortion along with problems for adjoining parts.

Detail: Your technological innovation provides for accurate command in the welding course of action, bringing about regular along with high-quality joint parts. To be able to help okay resources along with factors can make it suitable for industrial sectors using rigid good quality demands.

Zero Consumables: Ultrasonic welding won’t call for more resources similar to solder as well as adhesives. This specific eradicates the importance pertaining to consumables along with lowers squander, leading to personal savings along with ecological positive aspects.

Diminished Electricity Ingestion: The task eats a lesser amount of electricity in comparison with classic welding procedures, so that it is a ecological alternative pertaining to companies.

Issues along with Concerns

Even though ultrasonic welding gives many rewards, what’s more, it incorporates a list of issues:

Product Compatibility: Don’t assume all resources are generally well suited for ultrasonic welding. The task can be mostly powerful using mining harvests along with thermoplastics, as well as success may vary using the material’s components.

Tools Fees: Your initial expenditure throughout ultrasonic welding tools might be larger in comparison with a number of classic welding procedures. On the other hand, your long-term positive aspects regarding productivity along with diminished product fees generally outweigh your initial fees.

Mutual Energy: Even though ultrasonic welding supplies solid joint parts, the strength of your connect is determined by several components, which include product components along with course of action details. Guaranteeing best adjustments is important pertaining to accomplishing the desired mutual energy.

The longer term involving Ultrasonic Welding

While technological innovation is constantly on the improve, ultrasonic welding can be supposed to change along with develop their purposes. Enhancements throughout ultrasonic welding tools along with approaches will certainly increase their functions, so that it is well suited for a good much wider variety of resources along with purposes.

Integration using Automation: Your integration involving ultrasonic welding using robotic automation can be supposed to increase their productivity along with detail. Programmed devices could boost persistence along with minimize man miscalculation inside welding course of action.

Innovative Resources: Analysis straight into brand-new resources along with composites may result in your growth involving ultrasonic welding approaches which could take care of a new bigger various resources. This can throw open brand-new chances throughout industrial sectors including aerospace along with replenishable electricity.

Superior Command Devices: Advancements responsible for all devices along with detectors may help the detail along with suppleness involving ultrasonic welding, taking into account more advanced along with requiring purposes.

Finish

Ultrasonic welding has established themselves as being a transformative technological innovation throughout modern-day making, giving unmatched rate, detail, along with productivity. Via gadgets for you to aerospace, their purposes cover numerous industrial sectors, leading to enhancements along with improvements over several job areas. Even though issues continue being, on-going analysis along with engineering improvements offer to increase increase the functions along with purposes involving ultrasonic welding. While industrial sectors carry on and seek out useful along with ecological alternatives, ultrasonic welding is an acronym set for you to participate in a new vital position throughout by using the longer term involving making.

Leave a Reply